What is a filling machine? Benefits for businesses of filling machines

Filling machines are widely used in many manufacturing industries, including food and beverage, pharmaceutical, chemical, heavy industry, e-commerce. With the development of technology, various kinds of filling machines becoming more and more modern and advanced, bringing more benefits to businesses. So what is a filling machine? What benefits can filling machines bring to businesses? We invite you to find out in the following article!

1.About the filling machine

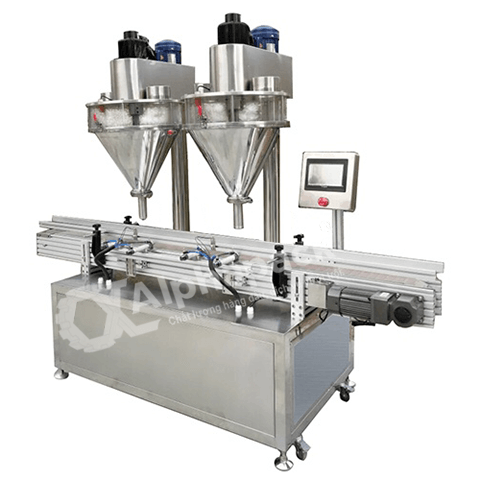

Filling machine is a device used to fill liquid, powder, granular, pellet, bag, film,… products into containers with a fixed flow. Filling machines are widely used in many manufacturing industries, including food and beverage, pharmaceutical, chemical, heavy industry, e-commerce.

2.Classification of filling machines

Filling machines are classified based on various criteria, including:

- Filling method: Filling machines can be classified into pump filling machines, gravity filling machines, pneumatic filling machines, vacuum filling machines, etc.

- Wattage: Filling machines can be classified into small, medium and large capacity filling machines.

- Automation: Filling machines can be classified into semi-automatic filling machines and automatic filling machines.

3.Advantage Filling Machine

Filling machines bring many benefits to businesses, including:

- Increase labor productivity: The filling machine helps to automate the filling process, reducing manual labor, increasing labor productivity many times. This helps businesses save labor costs, and can focus on other more important tasks.

- Product quality assurance: The filling machine helps to ensure the quality of the product being filled, avoiding contamination and damage. The filling machine is designed with advanced quality control systems, which help to ensure that the product is filled to the correct standards, without impurities or damage. This helps businesses improve their reputation and brand image.

- Increase product aesthetics: Filling machines can help enhance the aesthetics of the product being filled, helping to attract customers and increase sales. Filling machines can be designed with modern features, making the filling products more beautiful and eye-catching.

- Cost savings: Filling machine can help to save production cost. This is because filling machines can help reduce material and labor waste.

4.Selection of filling machine

To choose the right filling machine, businesses should pay attention to the following factors:

- Type of product to be filled: Filling machines have many different types, suitable for each specific type of product. Therefore, it is necessary to choose a filling machine suitable for the type of product to be filled.

- Filling machine capacity: The capacity of the filling machine needs to match the production needs of the business. If the capacity of the filling machine is too small, it will not be able to meet the production demand, resulting in production interruption. If the capacity of the filling machine is too large, it will waste investment costs.

- Automation: Filling machines can be classified into semi-automatic filling machines and automatic filling machines. Automatic filling machines are more expensive but bring higher efficiency. Therefore, it is necessary to consider production needs to choose a filling machine with an appropriate degree of automation.

- Operational Capability: The filling machine needs to be able to operate easily and conveniently. Therefore, it is necessary to choose a filling machine with a simple design and easy to use.

- Price: Filling machines have many different prices, depending on the brand, capacity, features,… Therefore, it is necessary to consider the factors that suit your needs and budget.

5.Structure of filling machine

The filling machine has a complex structure, consisting of many different parts. The main parts of the filling machine include:

Feeding system

The feeding system is responsible for bringing the product into the filling machine. This system can be implemented in various ways, such as by conveyor, by hand,…

Weighing and dosing system

The weighing and measuring system is responsible for accurately weighing and measuring the volume of products to be filled. This system can be implemented in various ways, such as by weight sensor, by hand,…

Filling system

The filling system is responsible for putting the product into the package. This system can be implemented in a variety of ways, depending on the type of product to be filled.

Sealing system

The sealing system is responsible for sealing the package after the product has been put in.

Label printing system, coding

Label printing and coding system is responsible for printing information on product packaging.

6.Popular types of filling machines

Based on the classification criteria, filling machines can be divided into the following common types:

Pump filling machine

This is the most common type of filling machine, using a pump to suck product from the tank and into the packaging. This method has the advantage of being able to fill a wide range of products, with high accuracy and relatively low cost.

Gravity Filling Machine

This method uses the product’s gravity to bring the product from the tank into the package. This method has the advantages of simplicity, ease of operation and low cost. However, this method is only suitable for low viscosity products.

Pneumatic filling machine

This method uses compressed air to push the product from the tank into the packaging. This method has the advantage of fast filling speed, suitable for products with high viscosity. However, this method has high technical requirements and relatively high cost.

Vacuum Filling Machine

This method uses vacuum to pull the product from the tank into the package. This method has the advantage that products with high viscosity can be extracted without air bubbles. However, this method has high technical requirements and relatively high cost.

Automatic Filling Machine

The automatic filling machine can operate fully automatically, without human intervention. The automatic filling machine has the advantages of high productivity, high accuracy and less labor.

Semi-automatic filling machine

The semi-automatic filling machine has some stages that are performed automatically, some other stages need human intervention. Semi-automatic filling machine has the advantage of being flexible, suitable for small and medium-sized businesses.

7.Modern filling machine technologies

The technologies used in filling machines are becoming more and more modern and advanced, bringing many benefits to businesses. Some common technologies used in filling machines include:

- Automatic control technology: Automatic control technology makes the filling machine work accurately and stably.

- Sensor technology: Sensor technology helps the filling machine to accurately control technical parameters, ensuring product quality.

- Printing technology: Printing technology helps the filling machine to print the necessary information on the product packaging.

- Maintenance technology: Maintenance technology helps the filling machine to be maintained and serviced periodically, ensuring the machine’s efficient and safe operation.

8.Epilogue

The filling machine is an important equipment in the manufacturing industries, helping to increase labor productivity, ensure product quality and save costs. With the development of technology, filling machines are becoming more and more modern and advanced, bringing many benefits to businesses.

Fertilizer production process

Fertilizer is an important factor in the agricultural industry, playing the role of providing necessary...

Beverage production process

Safe and High Quality Beverage Production Process Soft drinks have become an indispensable part of...

Paper Cup Production Process: From Paper to Environmentally Friendly Products

Introducing Paper Cups Paper cups are an environmentally friendly product widely used in coffee shops,...

Cosmetic Production Process

In the ever-evolving world of the cosmetics industry, the manufacturing process plays a key role...

Washing powder production process: From raw materials to finished products

Detergent is a cleaning chemical used to clean clothes and other items. The detergent production...

Beer production process

Beer is one of the most popular beverages in the world, produced from natural ingredients...