Top 10 best packaging machines today

Packaging machines are important equipment in production lines, helping to preserve products safely, conveniently, and enhance business efficiency. There are currently many types of packaging machines on the market with different features and prices. Below are the top 10 best packaging machines today, highly rated for quality, efficiency, and price.

Best packaging machines today – Top 10

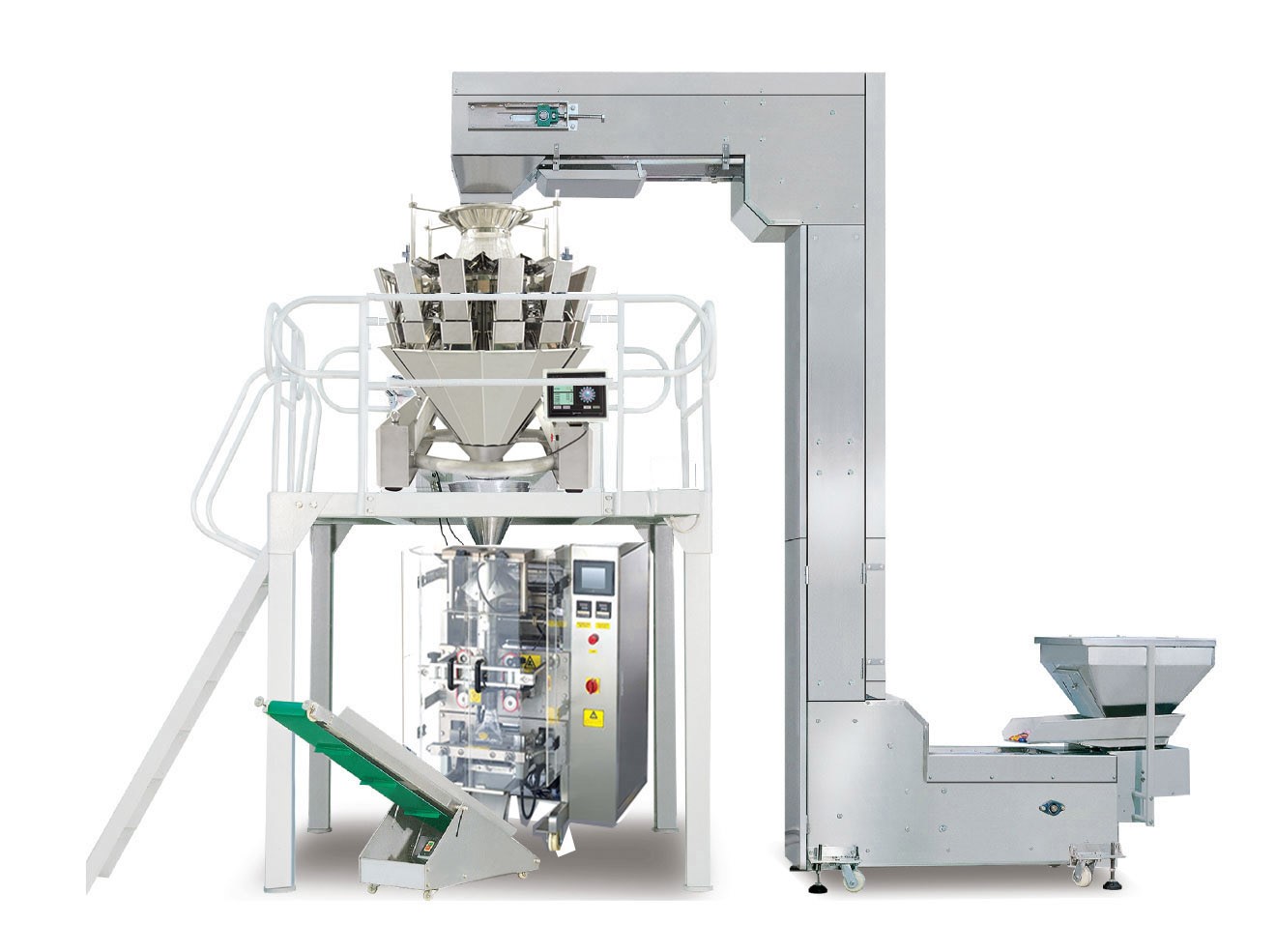

1. Automatic weighing packaging machine

The automatic weighing packaging machine is the most popular type of packaging machine today, widely used in the food, pharmaceutical, and cosmetic industries. The machine has the ability to accurately measure and automatically package according to the set weight, saving time and labor.

• Advantages:

o Accurate measurement, automatic packaging according to the set weight, saving time and labor.

o Suitable for various types of products, from food, pharmaceuticals to cosmetics.

o Can adjust packaging speed flexibly.

• Disadvantages:

o Higher cost compared to other types of packaging machines.

2. Vertical packaging machine

The vertical packaging machine is a type of packaging machine that uses a conveyor belt to move products to the packaging position. The machine has the ability to package quickly and efficiently, suitable for large-sized products with large volumes.

• Advantages:

o Quick and efficient packaging, suitable for large-sized products with large volumes.

o Can adjust packaging speed flexibly.

• Disadvantages:

o Requires more installation space.

3. Horizontal packaging machine

The horizontal packaging machine is a type of packaging machine that uses a conveyor belt to move products horizontally. The machine has the ability to package small-sized products with small volumes, suitable for the food, pharmaceutical, and cosmetic industries.

• Advantages:

o Packaging small-sized products with small volumes, suitable for the food, pharmaceutical, and cosmetic industries.

o Requires less installation space.

• Disadvantages:

o Slower packaging speed compared to vertical packaging machines.

The horizontal packaging machine

4. Pneumatic packaging machine

The pneumatic packaging machine is a type of packaging machine that uses the compressed air force to package products. The machine has the ability to package quickly and efficiently, suitable for large-sized products with large volumes.

• Advantages:

o Quick and efficient packaging, suitable for large-sized products with large volumes.

o Can adjust packaging force flexibly.

• Disadvantages:

o Higher cost compared to other types of packaging machines.

5. Vacuum packaging machine

The vacuum packaging machine is a type of packaging machine that uses vacuum suction force to remove air from the product, helping to preserve the product longer. The machine has the ability to package quickly and efficiently, suitable for fresh products, dry food, pharmaceuticals, etc.

• Advantages:

o Helps preserve the product longer, avoiding damage from bacteria and mold.

o Quick and efficient packaging, suitable for fresh products, dry food, pharmaceuticals, etc.

• Disadvantages:

o Higher cost compared to other types of packaging machines.

6. Pouch packaging machine

The pouch packaging machine is a type of packaging machine that uses laminated film to package products. The machine has the ability to package quickly and efficiently, suitable for small-sized products with small volumes.

• Advantages:

o Quick and efficient packaging, suitable for small-sized products with small volumes.

o Can package products with different characteristics, from food to pharmaceuticals.

• Disadvantages:

o Higher material costs compared to other types of packaging machines.

7. Shrink packaging machine

The shrink packaging machine is a type of packaging machine that uses shrink film to package products. The machine has the ability to package quickly and efficiently, suitable for large-sized products with large volumes.

• Advantages:

o Quick and efficient packaging, suitable for large-sized products with large volumes.

o Can package products with different characteristics, from food to cosmetics.

• Disadvantages:

o Higher material costs compared to other types of packaging machines.

8. Flat packaging machine

The flat packaging machine is a type of packaging machine that uses flat film to package products. The machine has the ability to package quickly and efficiently, suitable for large-sized products with large volumes.

• Advantages:

o Quick and efficient packaging, suitable for large-sized products with large volumes.

o Can package products with different characteristics, from food to cosmetics.

• Disadvantages:

o Higher material costs compared to other types of packaging machines.

9. Aluminum foil packaging machine

The aluminum foil packaging machine is a type of packaging machine that uses aluminum foil to package products. The machine has the ability to package quickly, efficiently, and is suitable for products that are easily damaged by sunlight and air, such as fresh food, dry food, pharmaceuticals, etc.

• Advantages:

o Helps preserve products from environmental impacts, from sunlight to bacteria and mold.

o Fast and efficient packaging, suitable for products that are easily damaged by sunlight and air, such as fresh food, dry food, pharmaceuticals, etc.

• Disadvantages:

o Higher cost compared to other types of packaging machines.

10. Air bag packaging machine

The air bag packaging machine is a type of packaging machine that uses air bags to package products. The machine has the ability to protect products from environmental impacts and is suitable for products that are easily damaged by impact, vibration, such as electronic devices, glassware, etc.

• Advantages:

o Protects products from environmental impacts, from impact, vibration to dust and mold.

o Suitable for products that are easily damaged by impact, vibration, such as electronic devices, glassware, etc.

o Can adjust the air bag tension flexibly.

• Disadvantages:

o Higher cost compared to other types of packaging machines.

Choosing the right packaging machine

When choosing a packaging machine, consider the following factors:

• Type of product to be packaged: Size, weight, and characteristics of the product will affect the choice of suitable packaging machine.

• Packaging speed: Choose a packaging machine with a suitable packaging speed according to production needs.

• Capacity: The packaging machine capacity needs to meet production needs.

• Cost: Compare the prices of different types of packaging machines before making a choice.

Above are the top 10 best packaging machines currently, highly rated for quality, efficiency, and price. Hopefully, this article will help you choose a packaging machine that suits your production needs.

Fertilizer production process

Fertilizer is an important factor in the agricultural industry, playing the role of providing necessary...

Beverage production process

Safe and High Quality Beverage Production Process Soft drinks have become an indispensable part of...

Paper Cup Production Process: From Paper to Environmentally Friendly Products

Introducing Paper Cups Paper cups are an environmentally friendly product widely used in coffee shops,...

Cosmetic Production Process

In the ever-evolving world of the cosmetics industry, the manufacturing process plays a key role...

Washing powder production process: From raw materials to finished products

Detergent is a cleaning chemical used to clean clothes and other items. The detergent production...

Beer production process

Beer is one of the most popular beverages in the world, produced from natural ingredients...