Outstanding benefits when using automatic labeling machines

Labeling machines are considered useful devices, saving time and manpower for manufacturing and business enterprises. Therefore, investing in this machinery is of interest to many units. The article will talk about the Outstanding benefits when using automatic labeling machines in import-export business

What is a labeling machine?

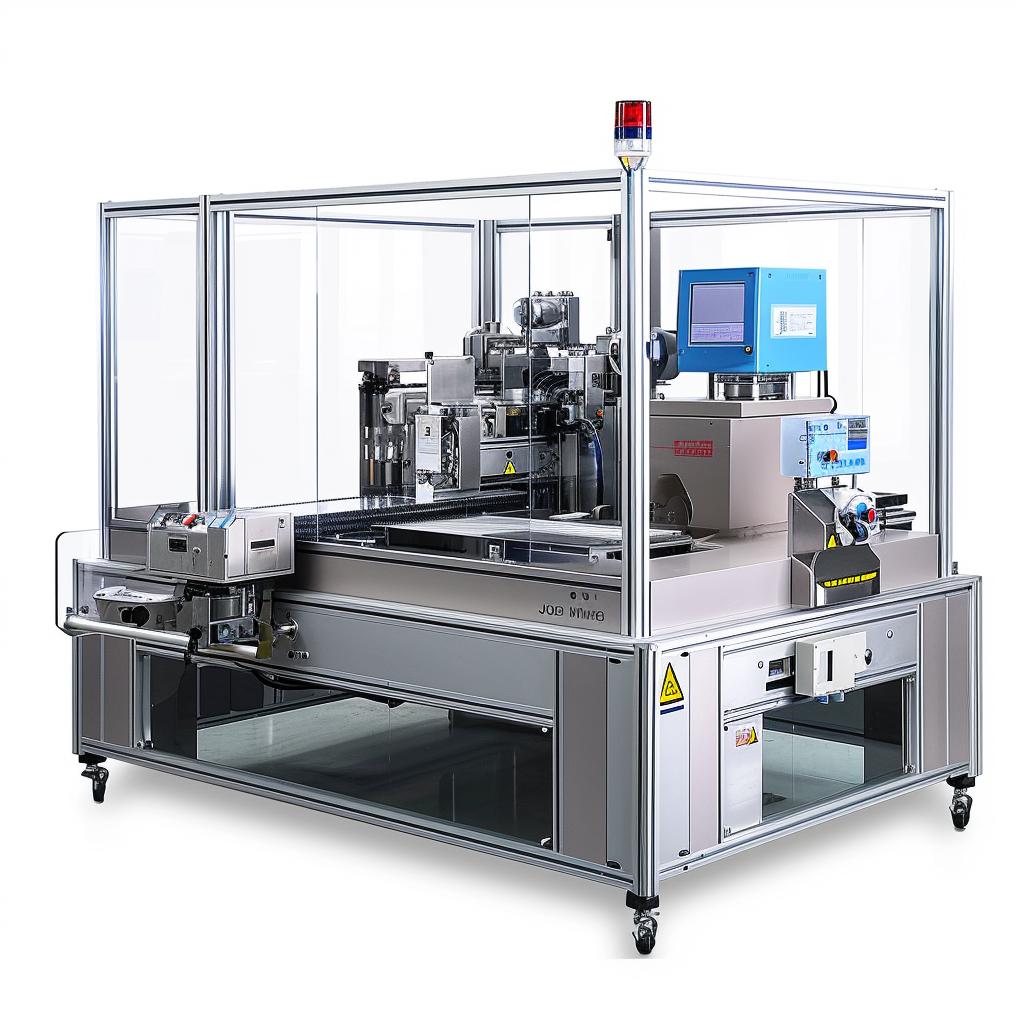

A labeling machine is a device that allows printing and affixing labels to products automatically, instead of manual labeling. The machine operates on the principle of computer control, using sensors to accurately locate and label the packaging.

Some popular types of labeling machines

Operating principle of labeling machine

- Prepare the product: Before the labeling machine begins the process, the product needs to be placed in the correct position on the conveyor belt or work table.

- Sensor detection:The machine is often equipped with sensors to identify the product and determine the exact location to place the label.

- Position the label: A mechanical or robotic system can be used to retrieve the label from the roll or label holder and position it based on information from the sensor.

- Labeling: After positioning, the machine will move the label to the required position on the product and apply pressure to adhere the label to the product surface.

- Compress and check: Some machines may use a compression system to ensure that the label is firmly adhered and that there are no air or air pockets between the label and the product surface. Some machines can also check label quality after application to ensure that everything is even and correct.

- Export products: Once the label has been applied, the product is moved out of the labeling machine’s working position to continue into the next manufacturing or packaging process.

Automatic labeling machines are often programmed to perform these steps automatically and accurately, minimizing human intervention and ensuring consistency in the production process.

Labeling machines are divided into 2 basic types:

Automatic labeling machine

Operates completely automatically, super fast with very high capacity, often used in large-scale factories and plants.

Semi-automatic labeling machine

Has human assistance and control, suitable for use in stores and small businesses.

Outstanding benefits when using automatic labeling machines

Using a labeling machine brings many of the following benefits and utilities:

Save time and labor

Automatic labeling machines do the job quickly and accurately, minimizing dependence on human labor. This helps increase efficiency and reduce labor costs.

Accurate and consistent

Automatic labeling machines reduce errors due to human factors, ensuring that each product is labeled consistently and accurately as required.

Enhance product quality

Enhance product quality Having accurate labels not only creates a positive impression on customers but also helps maintain product quality and consistency.

Increase inventory management capabilities

Automatic labeling machines can be integrated with inventory management systems, helping to track and manage the number of products in stock effectively.

Flexible and adaptive

Automatic labeling machines can be adapted to work with a variety of label types and product sizes, creating flexibility in the production process.

Increase production speed

Automating the labeling process speeds up production, reduces waiting times and increases responsiveness to fluctuating market demand.

Reduce waste and scrap

Do chính xác cao trong quá trình dán nhãn, máy dán nhãn tự động giảm rủi ro sản xuất sản phẩm không đạt chất lượng, giúp giảm lãng phí và phế liệu.

In addition, the machine also supports many different types of labels, and can customize the size and shape to suit each product.

Thus, using a labeling machine not only saves manpower but also increases production and business efficiency for businesses. At the same time, investing in machinery will also quickly bring profits and recover capital.

Fertilizer production process

Fertilizer is an important factor in the agricultural industry, playing the role of providing necessary...

Beverage production process

Safe and High Quality Beverage Production Process Soft drinks have become an indispensable part of...

Paper Cup Production Process: From Paper to Environmentally Friendly Products

Introducing Paper Cups Paper cups are an environmentally friendly product widely used in coffee shops,...

Cosmetic Production Process

In the ever-evolving world of the cosmetics industry, the manufacturing process plays a key role...

Washing powder production process: From raw materials to finished products

Detergent is a cleaning chemical used to clean clothes and other items. The detergent production...

Beer production process

Beer is one of the most popular beverages in the world, produced from natural ingredients...