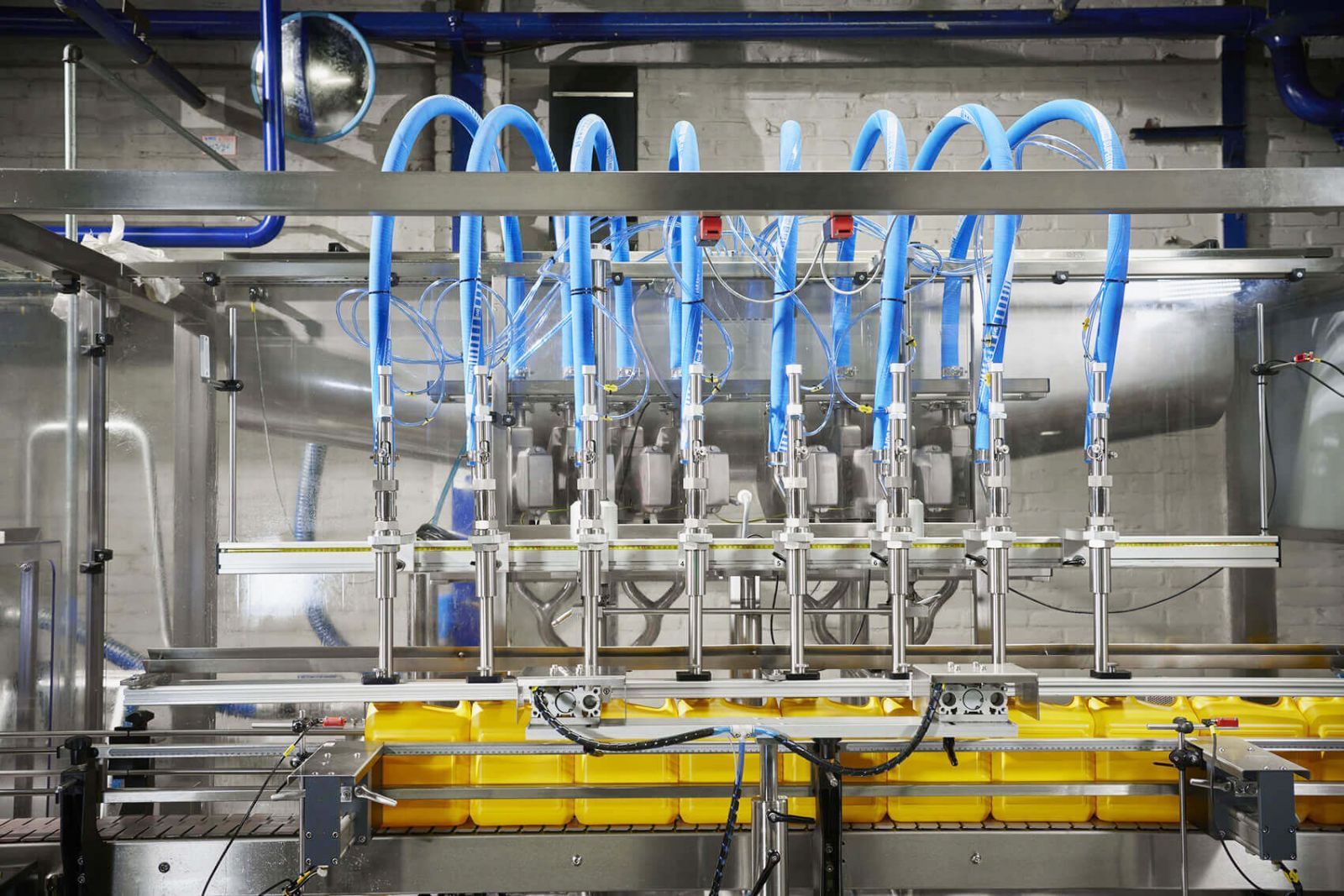

Common filling machine errors and effective troubleshooting

Filling machines are essential equipment in production and packaging lines. However, during use, filling machines may encounter some errors. This article will help you learn about common filling machine errors and effective troubleshooting.

Common filling machine errors

Here are some common filling machine errors:

- Dosage error: This is the most common error in filling machines. This error can be caused by a variety of factors, such as:

- Improper dosage parameters

- Damaged dosage equipment

- Uneven bottles

- Clamping error: This error occurs when the bottles are not held securely, leading to bottles falling, spilling, or breaking. This error can be caused by factors such as:

- Improper clamping parameters

- Damaged clamping equipment

- Uneven bottles

- Sensor error: This error occurs when the sensor does not function properly, leading to the filling machine not operating or operating incorrectly. This error can be caused by factors such as:

- Improper sensor parameters

- Damaged sensor equipment

- Sensor cable break

- In-out mechanism error: This error occurs when the in-out mechanism does not function properly, leading to bottles not being put into or taken out of the filling machine properly. This error can be caused by factors such as:

- Improper in-out mechanism parameters

- Damaged in-out mechanism equipment

- In-out mechanism cable break

How to troubleshoot filling machine errors

To troubleshoot filling machine errors, you can follow these steps:

- Check machine parameters: Check the parameters of the filling machine such as dosage parameters, clamping parameters, sensor parameters, and in-out mechanism parameters to ensure that these parameters are accurate.

- Check machine equipment: Check whether the equipment of the filling machine is damaged. If so, a new device needs to be replaced.

- Check bottles: Check whether the bottles are even. If not, the machine parameters need to be adjusted or new bottles need to be replaced.

Some tips for using filling machines

To reduce filling machine errors, you need to pay attention to the following issues:

- Use the machine correctly: Use the filling machine correctly according to the manufacturer’s instructions.

- Maintain and service the machine regularly: Regularly maintain and service the filling machine to ensure that the machine is operating properly.

- Use quality bottles: Use quality, even bottles to avoid causing errors for the filling machine.

Conclusion

– This article provides you with information on common filling machine errors and effective troubleshooting. Hopefully, this information will help you use the filling machine effectively and reduce machine errors. If you cannot fix common errors in the filling machine yourself, you should contact the supplier or warranty unit for support.

– Alphapack is a leading manufacturer and supplier of packaging and filling machines in Vietnam. In addition, the company also provides professional machinery warranty and maintenance services, helping customers feel secure in use. If you are looking for a reputable packaging and filling machine supplier or technical support, contact Alphapack for advice and support.

Alphapack Technology Engineering Joint Stock Company

Hotline: 0932.617.317 – 0942.388.979

Address: 685/9 National Highway 1A, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City

Email: info@alphapack.vn

Website: https://alphapack.vn/en

Fertilizer production process

Fertilizer is an important factor in the agricultural industry, playing the role of providing necessary...

Beverage production process

Safe and High Quality Beverage Production Process Soft drinks have become an indispensable part of...

Paper Cup Production Process: From Paper to Environmentally Friendly Products

Introducing Paper Cups Paper cups are an environmentally friendly product widely used in coffee shops,...

Cosmetic Production Process

In the ever-evolving world of the cosmetics industry, the manufacturing process plays a key role...

Washing powder production process: From raw materials to finished products

Detergent is a cleaning chemical used to clean clothes and other items. The detergent production...

Beer production process

Beer is one of the most popular beverages in the world, produced from natural ingredients...