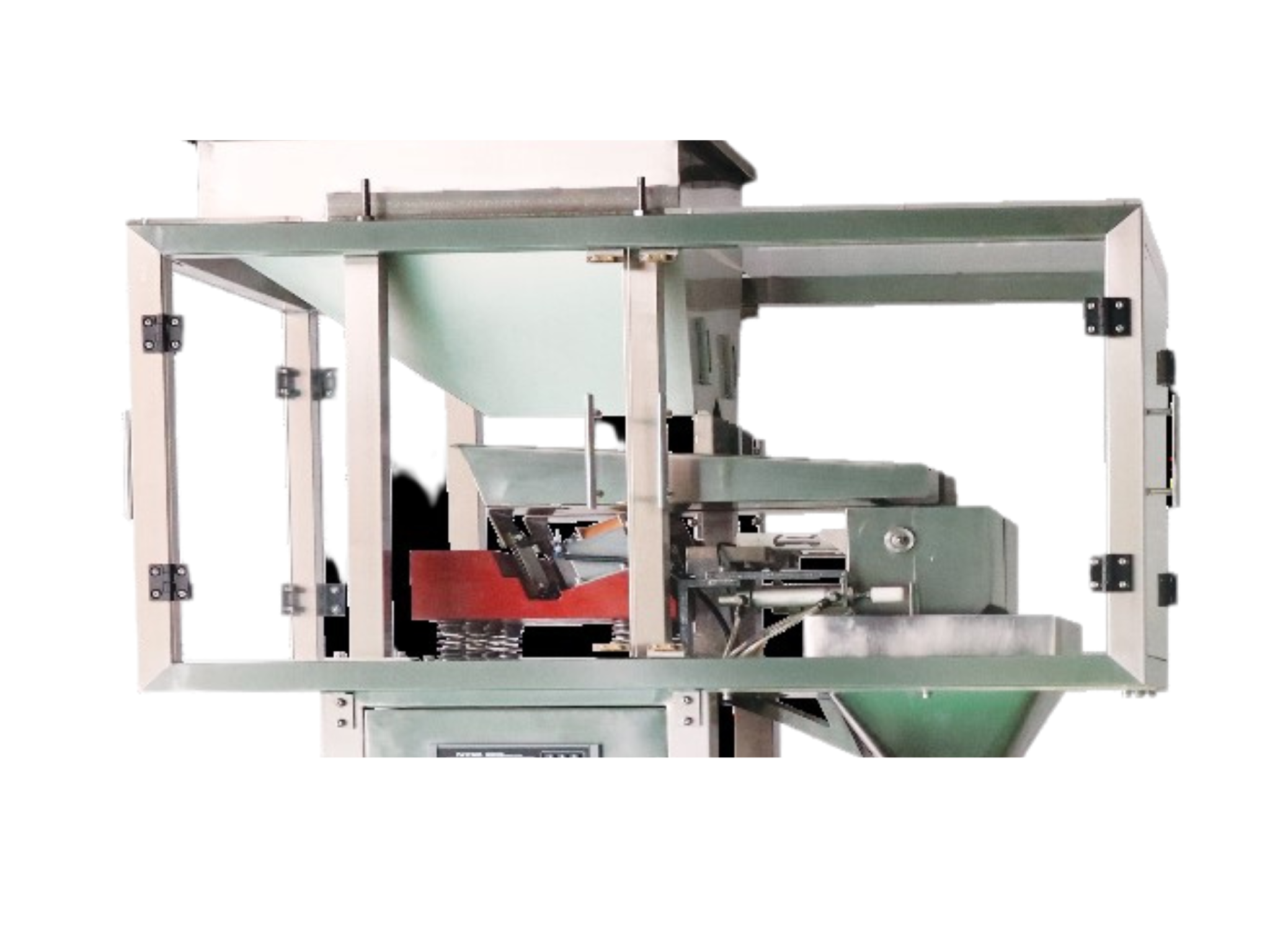

automatic pouch packing machine

The automatic pouch packing machine is a device that automates the process of packaging products into various plastic pouches, paper pouches, fabric pouches, etc. The machine operates fully automatically through an enclosed mechanical, pneumatic, and electronic system, minimizing human intervention.

Some features of the automatic pouch packing machine:

- Automatically measures and cuts pouches according to preset sizes

- Automatically opens pouch mouth and inflates before metering and packaging

- Has an accurate metering unit that puts products into pouches

- Automatically seals and heat seals pouch mouth after packaging

- Operates continuously, ensuring high output and accuracy

The machine is suitable for use in large-scale manufacturing plants that require packaging products at high speeds and with high precision.

Electrical Components

- PLC: Delta – Taiwan

- Loadcell: Cas – Korea

- Screen: Delta – Taiwan

- Inverter: Delta – Taiwan

- Sensor: Delta – Taiwan

- Power source: 220 or 380V, 50Hz

Quantitative

Quantitative Scale: used for grains, coffee, beans, sugar…

Measuring screw: flour, milk powder…

Piston pump: liquid, viscous

Loại túi:

| Model | 300 | 430 |

| Bag length (mm) | 100-300 | 100-430 |

| Bag width (mm) | 100-300 | 100-300 |

| Machine speed: bags/minute | 5-15 | 5-15 |

| Packaging weight(g) | 5-1500 | 5-2500 |

| Power requirement(kw) | 1kw | 1kw |

| Compressed air requirement(Mpa) | 0.6-0.8 | 0.6-0.8 |

| Machine weight(kg) | 450 | 500 |

| Machine dimensions (mm): L x W x H | 1880 x 510 x 2260 | 1880 x 550 x2300 |

Read more: Liquid packing machine

The automatic pouch packing machine plays a vital role in modern manufacturing and supply chain systems, offering numerous advantages that significantly enhance operational efficiency and product quality. One of the key benefits of this machine is its ability to automate the entire packaging process—from measuring and cutting pouches to filling and sealing—thus reducing the need for manual labor. This not only minimizes the risk of human error but also ensures consistency in packaging, which is crucial for maintaining product standards and brand reputation. Its high-speed operation, with the capability of processing up to 15 bags per minute, makes it especially suitable for large-scale production environments where time and precision are critical.

Another major advantage of the automatic pouch packing machine is its versatility. This flexibility is made possible through interchangeable metering systems such as quantitative scales, measuring screws, and piston pumps. Furthermore, the machine can accommodate a wide range of pouch sizes and materials, including plastic, paper, and fabric, making it adaptable to different packaging requirements across diverse industries.

In terms of applications, the machine is extensively used in food processing, pharmaceuticals, agriculture, chemicals, and consumer goods industries. Whether it is for packing coffee, sugar, detergent, sauces, or herbal products, the automatic pouch packing machine ensures that products are safely and hygienically packaged for distribution and sale. The precise metering unit and secure sealing system help extend shelf life and prevent contamination, which is particularly important for perishable goods.

The integration of high-quality electronic components, such as the Delta PLC and screen from Taiwan and CAS load cells from Korea, ensures durability, reliability, and user-friendly operation. Additionally, its compact design and moderate power and air requirements make it suitable for both standalone use and integration into larger automated production lines.

Overall, the automatic pouch packing machine is an indispensable tool in modern manufacturing. It enhances productivity, ensures packaging accuracy, and supports scalable production, thereby contributing to cost reduction, operational optimization, and improved product quality within the supply chain.